Projects

Uncompromising reliability and adherence to international engineering standards, enabling our clients to optimize their operations / facilities and deliver their projects within budget, time and to the right standard.

745kWP SOLAR PV INSTALLATIONS PROJECT SUMMARY

Project Name: CUMMINS WEST AFRICA LIMITED (CWAL) SOLAR PV INSTALLATIONS

Location: Plot Y, Mobolaji Johnson Ave, Alausa, Ikeja

Plant Size: 745kWP

Project Start Date: November 2021

Project Completion Date: January 2022

Introduction:

CWAL had a plan to install Three solar PV systems for the premises comprising an Office Block, rehouses, and a Workshop. The project was designed, procured, and supervised by Soventix Nigeria Limited.

The installation, Testing, and Commissioning of the Project components/element was done by Mundial Engineering.

The equipment installed is the Inverters, PV Modules, Cable Trays, Lifeline, Walkways, DC and LV Cables, Combiner Boxes, Control Boxes and installation and splicing of Fibre Comm cable. The area covered by the installation is about 2,564.46m2.

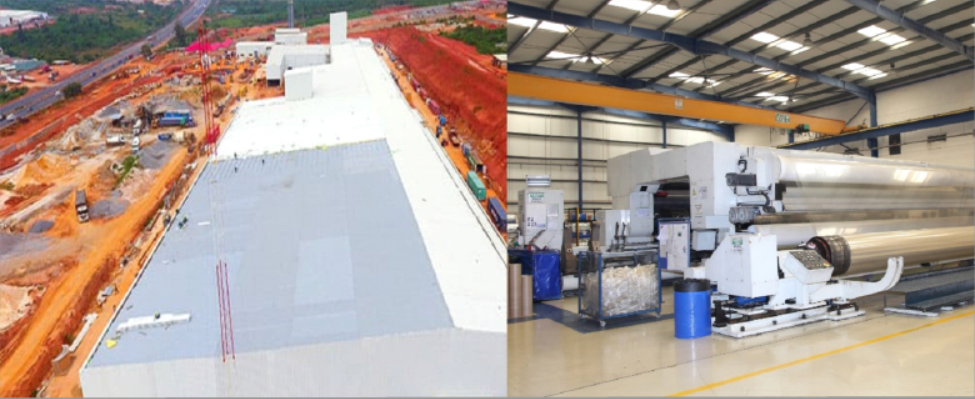

FLEXFILM FACTORY SAGAMU PROJECT SUMMARY

Project Name: Flexfilms Factory Development, Sagamu, Ogun State.

Location: Plan No. IJC 354(OG) Along Lagos/Ibadan

Project Start Date: August 2019

Project Completion Date: July 2021

Introduction:

Flex Films is the global film manufacturing arm of India’s largest multinational flexible packaging solutions company and global polymer science player, UFlex Limited.

The firm has state-of-the-art packaging film manufacturing facilities in all the major continents in the world. The Flexfilm Sagamu project is the second location in Africa after the plant in Egypt.

The Civil works was executed by Vita Construction and the MEP Installation works were executed by a few MEP contractors due to the timeline and wide project scope. Mundial Engineering was saddled with Electrical services installation, Testing and Commissioning of the Project.

The installation includes cable Trays, LV Panels, Sub-Main DBs, and various Distribution Boards controlling all Lighting, Emergency Lighting, and Small Power. There were dedicated film processing equipment connected to the Power supply and cable containment were laid to conceal the cables/ Wires. The first fix and second fix for Extra-Low Voltage services such as cable trays, GI Conduits and pulling of Data/IT/Fire Alarm cables were pulled to the locations as depicted on the working drawings.

BRITISH AMERICAN TOBACCO (BAT), IBADAN

Project Name: Installation of Flow Meters, Measurement Probes, Power Meters & Telemetry

Location: Ibadan, Oyo State.

Project Start Date: March 2020

Project Completion Date: June 2020

Introduction:

British American Tobacco, West and Central Africa (BAT WCA) is a part of the Americas and Sub-Saharan Africa region, one of the four regions that comprise the British American Tobacco (BAT) Group. The Group is a leading, multi-category consumer goods business. As part of its expansion plan, BATN engaged in the construction of a state-of-the-art factory in Ibadan, Oyo State. The factory was commissioned and began operations on June 17, 2003. Due to the need for process monitoring and proper alignment with the environment protection policy, the BAT WCA considered the deployment of measuring and monitoring devices (Flow meters, probes, Sensors, and energy meters). In March 2020, Mundial Engineering was engaged in the deployment of the devices required to achieve the project objectives.

This project details involved the installation of a utility metering & telemetry system at the site. In total the scope of the project includes 65 meters – 27 waters, 20 water meters which require modification, 3 New Steam meters, 10 Pressure and Temperature probes, 5 new air meters and 19 electric meters monitoring system requiring connection to internet. In addition to the physical meter installation, telemetry connections was made to each metering point using a combination of wireless pulse transmitters. Besides, two physical telemetry panels were installed to collect the data from the various site meters and export this data to Mundial’s energy management platform, Strata.

CONCORD ENVIRO – WASTE WATER RECOVERY PLANT

Project Name: GUINNESS NIG PLC WASTE WATER RECOVERY PLANT – BENIN & OGBA BREWERY

Location: Benin, Edo State and Ogba Ikeja, Lagos State.

Project Start Date: April 2021

Project Completion Date: Nov 2021

Introduction:

There is a need to reduce carbon Footprints and review the recycling of waste water within the Brewery located in Ogba and Benin. The Project for the treatment of the waste water was contracted to Concord Enviro.

The firm has worked in five (5) continents and deploying the water recovery solutions in many sectors such as Pharmaceuticals, Textiles, Distilleries, Automobiles, Food & Beverages and Oil & Gas.

The Concord Team engaged Mundial Engineering to support with the Installation of Electrical cables, Control Panels, LV Panels, Lighting, Cable Containment and Power Outlets.

Mundial Engineering Team worked on both Benin and Ogba Brewery for the Electrical Installations associated with the Waste Water Recovery Plant.

KIMBERLY CLARK – PROJECT MANGROVE

Project Name: Project Mangrove Development, Ikorodu, Lagos.

Location: Odogunyan, Ikorodu, Lagos.

Project Start Date: February 2020

Project Completion Date: January 2022

Introduction:

Kimberly-Clark Corporation is a multinational personal care corporation that produces mostly paper-based consumer products. The company manufactures sanitary paper products and surgical & medical instruments. Kimberly-Clark brand name products include Kleenex facial tissue, Kotex feminine hygiene products, Cottonelle, Scott and Andrex toilet paper, Wypall utility wipes, KimWipes scientific cleaning wipes and Huggies disposable diapers and baby wipes.

With the need for office and manufacturing in Nigeria, Kimberly-Clark engaged, ARUP Consultants, Vita Construction and MELCON MEP Consultants. The installation, Testing and Commissioning of the Project components/element was done by Mundial Engineering.

The installation involved Lighting, Small Power, 2Nos 3.1 5MVA Dry Transformers, 33kV Panel, 11kV Panel, Main LV Panel, Sub-Main Panel, Distribution Boards, UPS System, 12MVA Oil-Filled Transformer and all Cable Containments (GI Pipes/ Cable Tray/ Cable Ladders/ Trunking etc

FIRST BANK OF NIGERIA – NATIONWIDE ILLUMINATION UPGRADE AT BRANCHES

Project Name: First Bank of Nigeria LED Solar Street Light Installation

Location: Nationwide – North, South, East and West

Project Start Date: February 2021

Project Completion Date: In progress

Introduction:

To enhance sustainability and promote energy efficiency, First Bank of Nigeria embarked on an ambitious project to install solar streetlights in all her branches across the nation. This project aims to replace traditional grid-dependent streetlights with environmentally friendly and cost-effective solar-powered alternatives. The Solar Street Light Project is not just about illuminating the branches but represents a commitment to a greener, more sustainable future. Certainly, solar LED street lights come with a myriad of benefits, contributing to both environmental and economic sustainability.

Project Components:

High-efficiency solar panels are integrated into the LED Light design making the product a compact solution to capture and convert sunlight into electricity. Energy storage systems will be integrated to store excess energy generated during the day, ensuring continuous illumination during nighttime hours. The energy storage is also embedded within the housing of the LED lamps. Energy-efficient LED lights will replace conventional streetlights, providing bright and uniform illumination. Integral smart control systems is available to manage and optimize energy usage, allowing for dimming during low-traffic periods and brightening during peak hours.

CUMMINS NIGERIA – FLEXIPACK PROJECT

Project Name: PRJ119: Project Installation & Commissioning of 3x VAC(Chillers), 3xCooling Towers and 4 x 2MW Gas gensets, 2 x 1540KW gas gensets and 1 x 1.1MW Diesel genset.

Location: Agbara, Ogun State.

Project Start Date: March 2020

Project Completion Date: July 2020

Introduction:

Flexipack Ltd is intended to be the biggest BOPP + BOPET manufacturing plant in Africa. BOPP and BOPET films are specialty films that are used in various sectors such as packaging, industrial, electrical and electronics, food, beverage, pharmaceutical and medical, and personal care. BOPP films (Biaxially Oriented Polypropylene Films) and BOPET films (Biaxially Oriented polyethylene terephthalate) are polyester films that are majorly used for packaging, labeling, and lamination.

The factory is situated on Sixteen Hectares of land on the outskirts of Lagos, OPIC Industrial Estate in Agbara, Ogun State, Nigeria. Phase 1 of the factory measures 45,000 sqm and will house two lines each with a capacity of 54,000MT/year. ESOPP Group (France) handles the production technology.

In this BOPP (Biaxially Oriented Polypropylene) and BOPET (Biaxially Oriented Polyethylene Terephthalate) manufacturing plant, MEP installations are critical for maintaining a controlled environment, ensuring the functionality of machinery, and implementing safety measures. Here are key MEP installations in this Agbara facility:

The Power system comprises 4Nos 2MW Gas Gensets, 2Nos 1.54MW Gas Gensets, 1No 1.1MW Diesel Genset. The Electrical and Mechanical Enabling works associated with the Installation of Generator sets were done by Mundial Engineering under the oversight of Cummins Nigeria.

The following Electrical components were positioned and installed: Main Switch Board (MSB), ECDB Panel, 1600A Auxiliary Power Supply Distribution Panel, Ventilation Fans MCC panel, Radiator Fans MCC Panel, Mounting of Remote HMI Panels, Purge PLC Panels, Battery Chargers and Starter Batteries, Fire and gas detector panels, Gas genset cooling control panels (Amot panels). The task also included the Fabrication of Cable Support Structures, Cable Laying and Terminations, Equipment Earthing and Bonding, Installation of Fire and Gas Alarm System, Insulation Resistance Test, Pre-commissioning checks, and Commissioning support.

The Mechanical works associated with the Installation of the Generator sets involved 3Nos T450TR Vacuum Absorption Chillers (VAC) [Chiller capable of being fired by waste exhaust heat, Gas and Diesel- 14kW rated], 3Nos 18.5kW Cooling Towers, 5Nos. 457m3/hr Flow- 45kW rated Cooling Water Pump, 5Nos. 292m3/hr Flow- 37kW rated Chilled Water Pumps, 22Nos 4kW Ventilation Fans, 4Nos Flatbed Radiators For 2MW Gas Gensets, 2Nos Flatbed Radiators 1.54MW Gas Gensets, 3Nos Purge Fans.

GENERATOR RENTAL SERVICES: TEMPORARY OR LEASE-TO-OWN SCHEME

Introduction:

Our generator leasing service provides access to a fleet of high-quality generators with varying power capacities to meet diverse energy needs. Generators are sourced from reputable manufacturers, ensuring reliability, efficiency, and compliance with industry standards. Available generator types include diesel, natural gas, and hybrid models, offering flexibility to match specific power requirements.

Power Output and Load Management: Generators are capable of delivering a range of power outputs suitable for different applications, from standby power to prime power for continuous operation.

Advanced load management systems optimize fuel efficiency and adapt to varying power demands, ensuring cost-effective and sustainable energy provision.

Fuel Systems: Diesel generators feature efficient fuel delivery and consumption systems, equipped with fuel tanks designed for extended runtime. Natural gas generators provide a cleaner and more environmentally friendly power solution, with integrated fuel supply and monitoring systems.

Control and Monitoring Systems: State-of-the-art control panels with intuitive interfaces allow for easy operation and monitoring of generator performance. Remote monitoring capabilities enable real-time tracking of key parameters, facilitating proactive maintenance and minimizing downtime.

Environmental Compliance: Generators comply with local and international environmental regulations, incorporating emission control technologies to minimize ecological impact. Regular maintenance ensures optimal performance and adherence to environmental standards.

Installation and Integration: Our technical team conducts site assessments to determine the most suitable generator placement and integration with existing power systems. Professional installation services guarantee seamless connectivity and operational readiness.

Maintenance and Servicing: Scheduled maintenance programs are in place to uphold generator performance and extend equipment lifespan. Skilled technicians conduct routine inspections, load testing, and equipment upgrades as needed to ensure reliability during extended lease periods.

Fuel Management: Comprehensive fuel management services include fuel supply, monitoring, and optimization to guarantee uninterrupted power supply. Fuel quality control measures are implemented to safeguard generator efficiency.

Emergency Response and Technical Support: A dedicated technical support team is available 24/7 to address emergencies, troubleshoot issues, and provide timely solutions.

Rapid deployment of replacement units in case of equipment failure ensures continuous power supply.

Client: ABINBEV INTERNATIONAL BREWERY SAGAMU

Project Name: GENERATOR LEASING FOR POWER SUPPLY

Location: Various Locations within Nigeria

Start Date: November 2022

End Date: June 2023

Rental Duration: 8 Months

Introduction:

Generator Rental service tailored to meet the specific needs of ABINBEV International Brewery’s Packaging line in Sagamu. Our service proudly offers three powerful 1500kW Diesel Generators to ensure a seamless and uninterrupted power supply.

The Generator scheme was 2 Duty and 1 Stand-By set. The synchronization of the three sets was done in an electrical panel before the power is being fed into the Client Network.

With our service Offering, the Client was able to focus on brewing excellence while Mundial took care of powering the Packaging line.

The service also involved deployment two storage tanks: 5000 Litres and 3000 Litres tanks

Client: PZ CUSSONS INDUSTRIES, ODOGUNYAN, IKORODU

Project Name: GENERATOR LEASING FOR POWER SUPPLY

Start Date: August 2023

End Date: Dec 2023

Rental Duration: 5 Months

Introduction:

The Generator rental at PZ Cussons was tailored specifically for the production line of a Consumer Packaged Goods Factory requiring a 1200kW Diesel Generator. The Generator was a Dual fuel (Gas- Diesel) unit. It was running in Synchronization with other Generators within the Utility Yard. There are 5 Nos 1800kW Genbacher Gas Generator and 10 Nos 500kW Caterpillar Diesel Generators.

Due to the need for power to cater for the additional machines in the Soap production section, the 1200Kw Generator was deployed to serve the client for the duration of 5 Months.

Client: 1004 ESTATE DEVELOPMENT, IKORODU, LAGOS.

Project Name: GENERATOR LEASING FOR POWER SUPPLY

Start Date: December 2023

End Date: On-going

Rental Duration:

Introduction:

The 1004 Estate has an arrangement of Generators whose output are fed into step-up Transformers and the MV output is synchronized at the Panel in the Electrical Room. The synch Panel is equipped with capacity for a 6Nos 2MW Gen set. Due to the present condition of the Generators, there was a consensus to deploy 1No 1500Kw Generator to complement the power requirement for the Estate.

This will lead to the removal of 5Nos 500Kw Generators stationed at the front of each of the Estate blocks. The proposed Option of Power supply from Mundial is an interim 1 No 1500kVA Gen-set for the short-term solution. The long-term recommendation is a deployment of a 3Nos 1500Kw Generator working in 2Duty and 1 Standby mode.